Learn about Tea Processing: Creation of Tea

Tea leaves with a terminal bud and two young leaves are picked from the plant. This happens typically twice a year during early spring and early summer or late spring, which adds to the identification of the tea, as summer flush, spring flush, etc. The time of plucking creates a difference in the tea from other teas. Picking is done by hand for a high quality tea, or where labour costs are not prohibitive.

Depending on the skill of the picker, hand-picking is performed by pulling the flush with a snap of the forearm, arm, or even the shoulders, with the picker grasping the tea shoot using the thumb and forefinger, with the middle finger sometimes used in combination. Tea flushes and leaves can also be picked by machine, though there will be more broken leaves and partial flushes reducing the quality of the tea. However, it has also been shown that machine plucking in correctly timed harvesting periods can produce good leaves for the production of high quality teas.

Withering:

The tea leaves will naturally wilt soon after picking, with a gradual onset of enzymatic oxidation. However, it will be aided to wilt further for optimized condition of the leaf. Withering is used to remove excess water from the leaves and allows a very slight amount of oxidation. The leaves can be either put under the sun or left in a cool breezy room to pull moisture out from the leaves.

The leaves sometimes lose more than a quarter of their weight in water during withering. The process is also important in promoting the breakdown of leaf proteins into free amino acids and increases the availability of free caffeine, both of which change the taste of the tea. It takes 10 hours to 14 hours for physical and chemical changes to occur post which the tea is ready for the next stage.

Fixing:

Fixing the withered leaf is the process that provides tea with it’s flavour. Fixing facilitates in establishing proper conditions for enzymatic oxidation of the flavanols by atmospheric oxygen. The withered leaf is moderately heated. This deactivates their oxidative enzymes and removes unwanted scents in the leaves, without damaging and interfering with the natural flavour of the tea. Traditionally, the tea leaves are panned in a wok or steamed or baked or pan fired. Depending on the medium used to heat, the tea varies, the steamed ones have a vegetal taste while those pan-fried or baked have a toasty taste.

Oxidation:

The oxidation process which had begun during rolling is continued further in this stage. This process is sometimes referred to as "fermentation" in the tea industry. It takes place in separate fermentation rooms, which need to be kept extremely clean to avoid bacterial infection of the tea. It is conducted in a controlled temperature of 25-30º C in large rooms where humidity is 60-70%.

As soon as the tea has acquired a copper red colour, the correct degree of fermentation has been reached, and the process must be halted by drying. The tea producer may choose when the oxidation should be stopped, which depends on the desired qualities in the final tea as well as the weather conditions (heat and humidity). For light oolong teas this may be anywhere from 5-40% oxidation, in darker oolong teas 60-70%, and in black teas 100% oxidation. Oxidation is highly important in the formation of many taste and aroma compounds, which give tea its liquor colour, strength, and briskness. Depending on the type of tea desired, under or over-oxidation can result in grassy flavours, or strong wine like flavours.

Rolling:

In this stage, the form of tea is created. Rolling involves the process in which wilted leaves are gently rolled, and shaped with hand in wiry, kneaded, like rolled pellets, tied into balls, cones. The tea can also be pressed into bricks through the use of heavy stones or presses. The tighter the leaf is rolled, the longer they stay fresh. This stage helps the essential oils and sap to ooze out of the leaves, enhancing the taste further.

In many types of oolong, the rolled strips of tea leaf are then rolled to spheres or half spheres and is typically done by placing the damp leaves in large cloth bags, which are then kneaded by hand or machine in a specific manner.

Drying:

Drying helps in increasing the shelf life of tea as it makes it moisture free. This can be done by baking, panning, sunning and air drying. Commonly, it is baked in the industrial scale oven. This process requires great precaution as overheating or baking of tea can make it very harsh and take away from the natural flavour of the tea.

Curing or Aging:

This is only for some teas that require additional fermentation to reach consumption stage. For instance, a green tea puerh, prior to curing into a post-fermented tea, is often bitter and harsh in taste, but becomes sweet and mellow through fermentation. Oolongs too can benefit from aging if fired over charcoal. Flavoured teas also are manufactured in this stage by blending the flavourings into the tea with aromas and flavours.

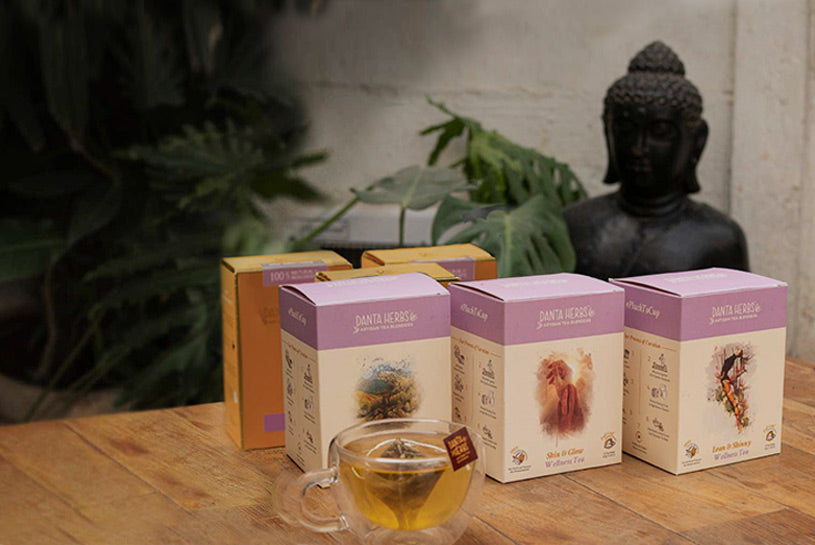

We at Danta Herbs bring you freshest leaves for your magical brew from the tea estates in Darjeeling, Nilgiris, Assam, Kangra, North east and Nepal.

FAQ’s:

Is tea fermented or oxidized?

While fermentation is also referred to in the production of brewed teas, this is inaccurate. Instead, harvested tea leaves undergo a natural chemical process known as oxidation, which also changes the color, flavor and level of health benefits in the resulting brew.

Which is the first step of processing in tea?

Tea leaf processing can be summarized in five steps: plucking, withering, rolling, oxidation, and drying. The actual production of tea, however, is a complex process with multiple steps to each phase. Also, note that production steps are also sometimes interchanged and repeated in treatments.

Is tea fermented or oxidized?

While fermentation is also referred to in the production of brewed teas, this is inaccurate. Instead, harvested tea leaves undergo a natural chemical process known as oxidation, which also changes the color, flavor and level of health benefits in the resulting brew.

Which is the first step of processing in tea?

Tea leaf processing can be summarized in five steps: plucking, withering, rolling, oxidation, and drying. The actual production of tea, however, is a complex process with multiple steps to each phase. Also, note that production steps are also sometimes interchanged and repeated in treatments.